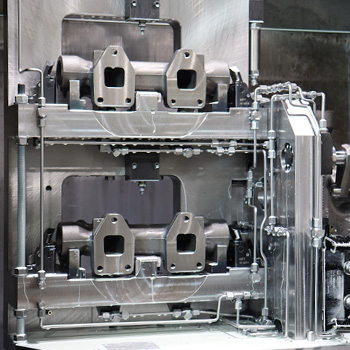

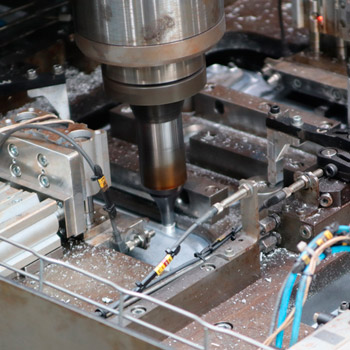

CNC machining and

module assembly – these are our core competences!

Our strength is the precise CNC machining of chassis and engine parts as well as parts for drive and e-mobility in combination with the subsequent module assembly. This specialization makes us a high-performance module supplier for the automotive industry, from development to serial production up to the individual parts.

For the CNC machining of castings, forgings and turned parts, the metalworking department currently has 130 CNC machining centres and 15 lathes. Coordinate measuring machines and internal testing facilities for materials and residual dirt analyses enable us to provide extremely comprehensive quality assurance.

Business activities:

- Process- and product development

- CAD-Systems in use: Creo Elements, Catia V5

- Own tool and fixture construction with design engineering

- Automation of manufacturing cells, large-scale production capability

- Supplier- and technical product management

- Multi-stage module assembly

- Cleanliness analyses, strength tests

- Leak testing

- Surface treatment/impregnation by proven partners

- Prototype production, spare parts supply

Production equipment:

- 130 CNC machining centres

- 25 Assembly stations

- 15 CNC lathes

- 2 Friction welding systems

- 1 Broaching machine (internal gearing)

- 8 Measuring devices by Zeiss

- 1 Laboratory

- 5 Tool milling machines

- 10 Industrial cleaning machines

- 25 Industrial robots

- 1 Crack detection machine for steel parts